650P

Crawler Dozer

- Net Power: 78 kW (104 hp) at 1,900 rpm

- Operating Weight: 9600–10 198 kg (21,165–22,484 lb.)

- Track on Ground: 2 626 mm (103 in.)

Features

Left engine compartment

Left engine compartment

Right engine compartment

Right engine compartment

650 P left & right engine compartments with access to engine oil dipstick, fill, and filter

650 P right service door with access to vertical spin on fuel, hydraulic, and hydrostatic transmission filters and fill

650 P right service door with access to vertical spin on fuel, hydraulic, and hydrostatic transmission filters and fill

650 P left service door with access to electrical system and DEF tank with service light switch

650 P left service door with access to electrical system and DEF tank with service light switch

Efficient and cleanly routed harnesses and hoses to minimize rub and leak points under the cab floor plate

Efficient and cleanly routed harnesses and hoses to minimize rub and leak points under the cab floor plate

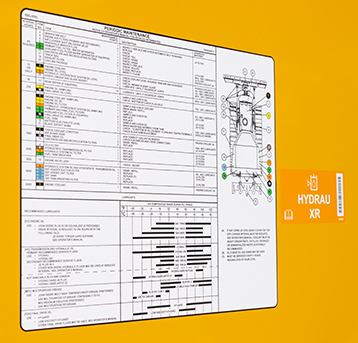

John Deere small dozers host many improvements made to simplify maintenance and improve uptime, building upon the durability that customers have come to appreciate with their John Deere Dozers. Maintenance items are conveniently located for easy access using vertical spin-on type filters. Hose and harness routings have been optimized to reduce rub and leak points, ensuring your machine stays up and running longer. The color-coded periodic maintenance chart includes relevant information such as maintenance intervals, refill capacities, and fluid recommendations to help ensure maintenance gets done correctly and on-schedule.

Benefits

- Reduced maintenance costs with extended hydraulic oil change interval of 4,000 hours (from 2,000 hrs.) throughout John Deere’s small dozer lineup

- Reduced likelihood of fluid leaks and hose failures due to the optimized harness and hose routings throughout the machine

- Ground level filter access, using vertical spin-on style filters makes maintenance straightforward

John Deere dozers provide customers a periodic maintenance chart located on the inside of the right service door

John Deere dozers provide customers a periodic maintenance chart located on the inside of the right service door

John Deere 650 P dozer cab with heated and ventilated seat

John Deere 650 P dozer cab with heated and ventilated seat

John Deere 650 P dozer cab provides superior visibility

John Deere 650 P dozer cab provides superior visibility

Premium Bluetooth radio with microphone and automatic temperature control HVAC system

Premium Bluetooth radio with microphone and automatic temperature control HVAC system

12-volt power port with USB, radio auxiliary port, and cell phone holder

12-volt power port with USB, radio auxiliary port, and cell phone holder

Sealed switch module simplifies wiring and reduces the use of mechanical switches, while centrally locating machine settings

Sealed switch module simplifies wiring and reduces the use of mechanical switches, while centrally locating machine settings

John Deere’s lineup of small dozers boast a redesigned cab with enhanced visibility, and many creature comforts to keep operators at ease even through the toughest tasks. Plenty of updates were made to the latest generation dozer cab to keep operators productive and comfortable throughout the work week.

Benefits

- Comfort – An enhanced heated & ventilated seat with leather surround and automatic temperature-controlled HVAC system will keep operators refreshed every time they get in the cab. The updated cab is 14% larger for convenient storage space and easier ingress/egress.

- Maximum visibility – An added LED light package along with a redesigned hood profile that is lowered, provides exceptional visibility. All of this with an added rear-view camera that is displayed on a larger and brighter 203-mm (8-in.) touchscreen monitor provides more awareness on busy jobsites.

- The re-profiled hood has been dropped 127 mm (5 in.) on the 650 P and 178 mm (7 in.) on the 450 P and 550 P improving overall forward visibility.

- Sealed Switch Module (SSM) - Reduces complexity by significantly reducing the number of wires and mechanical switches while also allowing low-effort control of keyless start. Avoids scattering switches throughout the cab and conveniently centralizes buttons which enable features such as automatic turbocharger cool-down, auto shutdown, auto idle, and eco mode

- Advanced display – The NEW 203-mm (8-in.) touch-screen display makes navigation and interacting with slope control easy. The new monitor displays the rear-view camera, slope control (if equipped), and machine configurable settings.

- Configurable hydraulic and transmission settings – Every operator is different, with varying techniques and preferences. We’re accommodating. Adjustable hydraulic and transmission response settings that can be tailored to any operator preference.

- Updated controls – Operators will appreciate the proportional blade angle roller switch, and a rocker switch to change travel direction; all integrated into low effort ergonomically designed joysticks.

450 P & 650 P dozers with updated and lowered hood profile

450 P & 650 P dozers with updated and lowered hood profile

650 P dozer front view

650 P dozer front view

View from inside the updated cab of John Deere’s small dozer lineup

View from inside the updated cab of John Deere’s small dozer lineup

John Deere has improved front visibility on the latest small dozer P-Tier lineup by lowering and re-profiling the hood. Without significantly changing the appearance of the dozers, operators will notice a considerable difference in forward visibility over the previous generation. Along with the front of the hood being dropped, the hood profile was also redesigned to provide straight sightlines to the front of the machine. The added visibility allows the operator to focus on task in front of them and increases situational awareness.

Benefits

The increased glass area on the front window and reprofiled hood allows the operator to see closer to the front of the machine and improves overall visibility.

- The hood has been dropped 127 mm (5 in.) on the 650 P compared to its previous model

- The hood has been dropped 178 mm (7 in.) on the 450 P and 550 P compared to previous models

John Deere 650 P Dozer with EZ Grade and Slope Control technology

John Deere 650 P Dozer with EZ Grade and Slope Control technology

Technology offerings integrated into easy-to-use touchscreen displays

Technology offerings integrated into easy-to-use touchscreen displays

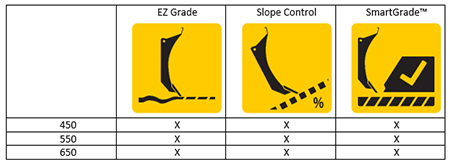

Improve efficiency and complete tasks easier using the latest technology on John Deere’s small dozers. John Deere precision construction technology is upgradeable, allowing customers to add technology over the machine’s lifecycle. From standard EZ Grade to optional slope control and 3D SmartGrade™, grade management technology helps solve labor challenges by simplifying operation and making it easier to achieve the desired grade.

- EZ Grade – Standard on EH controlled small dozers, EZ Grade simplifies operation and makes it easier to grade smooth finish passes by automating blade movements and correcting for changes in the machines pitch.

- Slope Control – Assists operators in maintaining desired slopes, both main and cross slopes. Slope control can be used in multiple ways.

- Live Mode - gives operators a visual indicator of the machines slope, allowing operators to manually maintain and carry out their preferred slope.

- Target Mode - allows the operator to set a target blade slope while the system automatically controls the blade to maintain the set target.

- Joystick Mode – allows operators to grade manually with the system automating blade movements to maintain the grade of the last operator input.

- SmartGrade™ - John Deere’s fully integrated 3D GNSS grade control system. SmartGrade integrates harnesses and components into the machine for added convenience, making external masts or harnesses a thing of the past. The enhanced feature set of Auto SmartGrade enables novice operators to push more material each pass. SmartGrade can be installed via upgrade kit on existing dozers, see your dealer for details.

- SmartGrade Remote Support – New to SmartGrade? Looking for improved support capabilities? SmartGrade dozers come standard equipped with both remote display access & wireless data transfer. Grant support access to anyone within your company or local dealer.

- Remote Display Access – Remotely view and control the SmartGrade display to easily troubleshoot issues and train operators.

- Wireless Data Transfer – Wirelessly transfer files such as project files and updates to 3D models both to and from the machine.

- SmartGrade Remote Support – New to SmartGrade? Looking for improved support capabilities? SmartGrade dozers come standard equipped with both remote display access & wireless data transfer. Grant support access to anyone within your company or local dealer.

EZ Grade, Slope Control, and SmartGrade availability

EZ Grade, Slope Control, and SmartGrade availability

*EZ Grade is standard, while Slope Control and SmartGrade™ are optional.

450 P dozer with extended life undercarriage using SC-2 coated bushings

450 P dozer with extended life undercarriage using SC-2 coated bushings

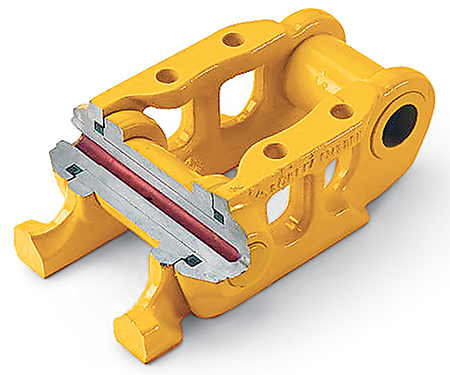

Every operation is different, but everyone’s goals are aligned…maximize undercarriage life and reduce downtime. John Deere offers a variety of undercarriage options to help balance component wear to get the most life possible out of components before performing maintenance. Weather you plan to complete a bushing turn or intend to run until a replacement is needed, John Deere’s undercarriage offerings are intended to improve the ownership cost of your machine.

- Standard Heavy-Duty – Uses a sealed and lubricated track chain with hardened steel pins/bushings and polyurethane seals to keep lubrication in and abrasives out.

- Extended Life – Uses proprietary SC-2 coated bushings designed to double the bushing life compared to standard bushings. The extended bushing life allows you to maximize the wear life of other undercarriage parts.

- Maximum Life – Provides the same benefits as extended life with the use of SC-2 coated bushings, along with larger components with more wear material on the rollers (upper & lower), chain links, idlers, and seals.

Standard heavy-duty sealed and lubricated track chain cut-away

Standard heavy-duty sealed and lubricated track chain cut-away

Extended Life and Maximum Life SC-2 coated bushings provide increased wear resistance

Extended Life and Maximum Life SC-2 coated bushings provide increased wear resistance

Blue areas of Maximum Life components illustrate the added wear material

Blue areas of Maximum Life components illustrate the added wear material

Specifications

Compare the specifications of up to 4 models

| DRIVELINE | 650p Current Model |

|---|---|

| Engine Manufacturer | John Deere |

| Engine Model | PowerTech PWS 4045 |

| Displacement, ltr (Inches³) | 4.5 (276) |

| Rated Speed, rpm | 1900 |

| Engine Output - Net, kW (hp) | 78 (104) |

| Transmission Type | Hydrostatic |

| Speeds Mode 1 - Forward | 1 |

| Speeds Mode 1 - Reverse | 1 |

| Final Drive | Triple Reduction |

| Track Rollers | 7 |

| Shoe - Pitch, mm (inches) | 171 (6.7) |

| Shoe - Type | Single Grouser |

| Ground Contact Area, cm² (Inches²) | 37336 (5787) |

| Number Of Shoes | 40 |

| DIMENSIONS | |

| Height - Max, mm (ft/in) | 2899 (9 ft 6 in) |

| Ground Clearance, mm (inches) | 345 (13.6) |

| Track Length - On Ground, mm (ft/in) | 2626 (8 ft 7 in) |

| Length - PAT Blade Straight, mm (ft/in) | 4250 (13 ft 11 in) |

| Track Gauge, mm (ft/in) | 1753 (5 ft 9 in) |

| Blade - Width, mm (ft/in) | 2921 (9 ft 7 in) |

| Blade - Dig Depth, mm (inches) | 538 (21.2) |

| Blade - Tilt, mm (ft/in) | 393 (1 ft 3 in) |

| CAPACITIES | |

| Fuel Tank, ltr (gallons (US)) | 202 (53.45) |

| Blade - Capacity, m³ (yd³) | 2 (2.6) |

| PERFORMANCE | |

| Speed - Forward Maximum, kph (mph) | 8 (5) |

| Speed - Reverse Maximum, kph (mph) | 8 (5) |

| Ground Bearing Pressure, kPa (PSI) | 44.1 (6.4) |

| Implement Pump - Type | Gear |

| Implement Pump - Flow, lt/min (gallons (US) / min) | 71.5 (19) |

| WEIGHTS | |

| Operating Weight, kg (lbs) | 10198 (22484) |